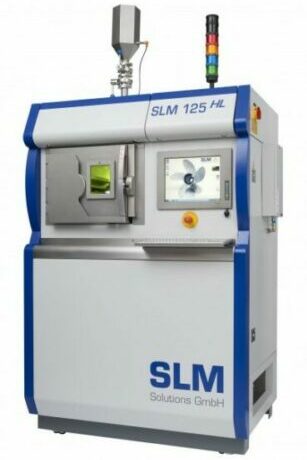

DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting) are additive manufacturing methods. They create 3D metal-printed parts by aggregating fine particles of metal powder, which are then welded together.

The laser is used to sinter a layer of material which is the first to be deposited on the tray. The tray then moves down a notch, and a rake deposits a layer on top of the first layer already present. The laser fuses the two layers together to create a three-dimensional object.

The powder used is a metallic powder. This technique can be used to print metal parts such as aluminum, stainless steel and steel, as well as bronze, gold, etc.

Sintered metal 3D printing is used in industrial production, because the resulting metal parts are as strong as those produced by conventional manufacturing techniques such as machining or casting.

This technology offers major advantages over traditional production techniques, as even complex objects can be produced in a single cycle, thus reducing production costs. It also offers the possibility of printing geometries and structures that cannot be milled on a CNC machine.

Metal sintering 3D printing combined with topological analysis enables lighter parts to be produced than with conventional manufacturing methods.

Please contact us to define the material and finishes you wish to use among these different varieties:

For the dimensions of your parts, we are able to comply with standard NFT 58-000 normal class.

For the Metal Sintering process, please allow 2 to 6 working days, depending on the size and finish of your project. For mini series (up to a few hundred pieces, please contact us for lead times).

For the design of your parts, plan for a minimum wall thickness of 0.8 mm.

To find out more about our other additive manufacturing production resources, please visit our our machines page.

Need a quote or information on rapid prototyping?

Ask us for a quick quote or call us on +33 (0)5 55 06 17 17