At Axis, our core business is producing parts for rapid prototyping.

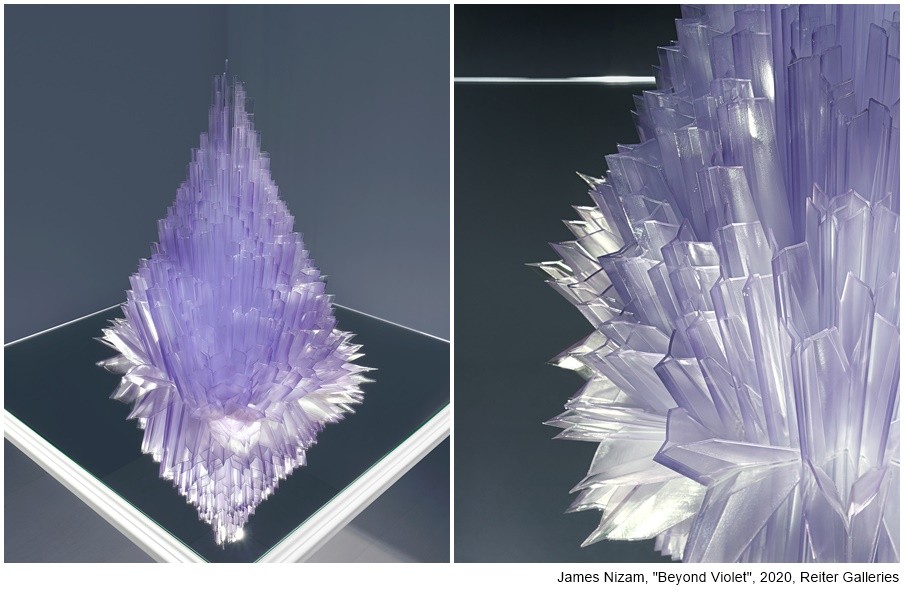

However, we sometimes have aesthetic, even artistic, pieces to produce. They have a purpose other than serving as a “test” for subsequent injection projects. This was the case in our collaboration with James Nizam.

James Nizam is a complete artist of Canadian origin. He uses photography, sculpture and architecture to create his works. The artist is renowned for his work with light and space, including Shard of Light (2011) and Sundial (2013). In particular, he uses various photographic processes to create unique works.

Stereolithography was the ideal 3D printing technique for producing this sculpture.

The latter had to combine precision of detail and aesthetic appeal with the best possible rendering.

The “Beyond Violet” sculpture was produced using an additive manufacturing process known as stereolithography. This technique uses a laser to harden a resin in successive layers of 0.10 to 0.15 mm. The material used here was Accura Clearvue, which produces colorless translucent parts without any finishing. Depending on the different treatments and finishes applied to the parts produced, different opacities can be obtained. This can vary from opalescent to completely transparent, when it is possible to varnish all surfaces of the same part.

For the finishing touches, we carry out a number of tests beforehand, in order to obtain our customer’s approval for the final project. This part is particularly long and tedious to produce, both in terms of 3D printing and finishing. We therefore carried out several tests using only samples of the final part. To achieve such a translucent, tinted finish, we had to apply a varnish in which we mixed a certain dosage of violet paint, according to a Pantone color reference requested by the artist.

Axis is therefore able to work hand in hand with all kinds of customers in a wide variety of fields. Don’t hesitate to contact us for the realization of your projects via our form or e-mail address axis@axishello.com.